How an electric lift truck’s battery is recharged for continued commercial use has a major effect on how efficiently a business can operate, especially if there are any battery charging station requirements.

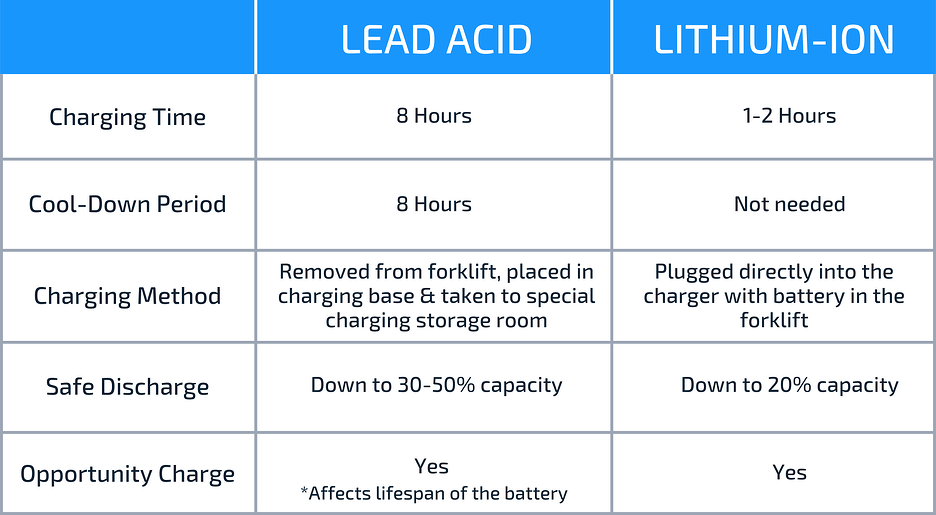

As you can imagine, lithium-ion batteries are the newer of the two types of battery technology, so their charging is faster and less complicated. Let us take a look at how charging is different between these two forklift battery types:

Lithium-ion batteries can be opportunity charged and do not need to be recharged to 100% forklift battery capacity.

Lead acid batteries must not be disconnected from their forklift battery charger until they have reached full forklift battery capacity and in most cases cannot be opportunity charged.

Moreover, if either of these types of batteries are not charged correctly, they will deteriorate in quality as time goes by – with lead acid units having much stricter guidelines when it comes to the required charging technique.

Forklift Battery Charging Station Requirements

The physical location of your forklift battery charger system is a much bigger consideration than many business owners realize.

Lead acid batteries have specific forklift battery charging station requirements that lithium-ion battery packs do not. After all, lithium-ion battery packs are plugged straight into a charger, and they do not need to be removed from the lift truck to start recharging. There are not really any further actions that need to be taken in order to do a simple recharge.

With lead acid forklift batteries, however, the units must be removed from the vehicle completely and placed onto a separate forklift battery charger – many of which have the ability to perform equalization. If there are many forklifts in operation, then there will need to be multiple chargers as well as a space for multiple units to cool down after fully recharging. This will involve employees having to use special lift equipment to pick up discharged batteries and drop in charged batteries on a regular basis. While it is not physically straining the task is time-consuming to operations wanting to be more productive.

Lead acid batteries need a dedicated charging space that ventilates and controls the temperature in the room. This is because lead acid batteries can get very hot while charging, producing harmful fumes.

Lithium-ion forklift batteries do not need a separate space, do not need to cool down, and do not require a fully-charged spare at the ready when another one fully discharges – it can be recharged on the spot.

Post time: Dec-23-2022