With the rapid development of the lithium battery industry, the application scenarios of lithium batteries continue to expand and become an indispensable energy device in people’s lives and work. When it comes to the production process of customized lithium battery manufacturers, the lithium battery production process mainly includes ingredients, coating, sheeting, preparation, winding, shelling, rolling, baking, liquid injection, welding, etc. The following introduces the key points of the lithium battery production process. Positive electrode ingredients The positive electrode of lithium batteries is composed of active materials, conductive agents, adhesives, etc. First, the raw materials are confirmed and baked. Generally speaking, the conductive agent needs to be baked at ≈120℃ for 8 hours, and the adhesive PVDF needs to be baked at ≈80℃ for 8 hours. Whether active materials (LFP, NCM, etc.) require baking and drying depends on the state of the raw materials. At present, the general lithium battery workshop requires temperature ≤40℃ and humidity ≤25%RH. After drying is completed, PVDF glue (PVDF solvent, NMP solution) needs to be prepared in advance. The quality of PVDF glue is critical to the internal resistance and electrical performance of the battery. Factors that affect glue application include temperature and stirring speed. The higher the temperature, the yellowing of the glue will affect the adhesion. If the mixing speed is too fast, the glue can be easily damaged. The specific rotation speed depends on the size of the dispersion disk. Generally speaking, the linear speed of the dispersion disk is 10-15m/s (depending on the equipment). At this time, the mixing tank is required to turn on the circulating water, and the temperature should be ≤30°C.

Add the cathode slurry in batches. At this time, you need to pay attention to the order of adding materials. First add the active material and conductive agent, stir slowly, then add the glue. The feeding time and feeding ratio must also be strictly implemented according to the lithium battery production process. Secondly, the rotation speed and rotation speed of the equipment must be strictly controlled. Generally speaking, the dispersion linear speed should be above 17m/s. This depends on the performance of the device. Different manufacturers vary greatly. Also control the vacuum and temperature of the mixing. At this stage, the particle size and viscosity of the slurry need to be regularly detected. The particle size and viscosity are closely related to the solid content, material properties, feeding sequence and lithium battery manufacturing process. At this time, the conventional process requires temperature ≤30℃, humidity ≤25%RH, and vacuum degree ≤-0.085mpa. Transfer the slurry to a transfer tank or paint shop. After the slurry is transferred out, it needs to be screened. The purpose is to filter large particles, precipitate and remove ferromagnetic and other substances. Large particles will affect the coating and may cause excessive self-discharge of the battery or risk of short circuit; too much ferromagnetic material in the slurry may cause excessive self-discharge of the battery and other defects. The process requirements of this lithium battery production process are: temperature ≤ 40°C, humidity ≤ 25% RH, screen mesh size ≤ 100 mesh, and particle size ≤ 15um.

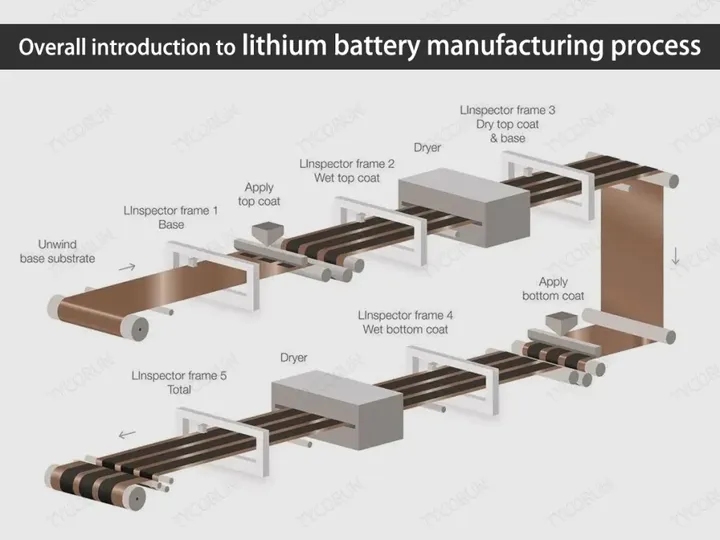

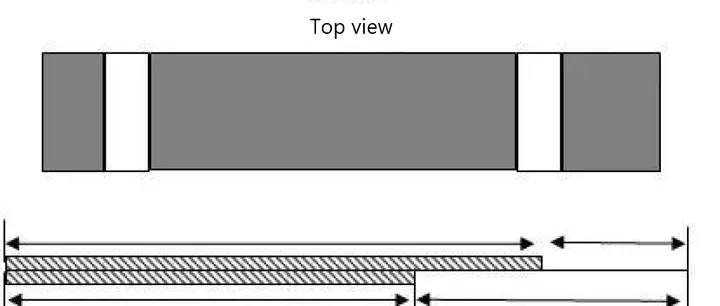

Negative electrode ingredients The negative electrode of lithium battery is composed of active material, conductive agent, binder and dispersant. First, confirm the raw materials. The traditional anode system is a water-based mixing process (the solvent is deionized water), so there are no special drying requirements for the raw materials. The lithium battery production process requires the conductivity of deionized water to be ≤1us/cm. Workshop requirements: temperature ≤40℃, humidity ≤25%RH. Prepare glue. After the raw materials are determined, the glue (composed of CMC and water) must first be prepared. At this point, pour the graphite C and conductive agent into a mixer for dry mixing. It is recommended not to vacuum or turn on circulating water, because the particles are extruded, rubbed and heated during dry mixing. The rotation speed is low speed 15~20rpm, the scraping and grinding cycle is 2-3 times, and the interval time is ≈15min. Pour the glue into the mixer and start vacuuming (≤-0.09mpa). Squeeze the rubber at a low speed of 15~20rpm for 2 times, then adjust the speed (low speed 35rpm, high speed 1200~1500rpm), and run for about 15min~60min according to the wet process of each manufacturer. Finally, pour the SBR into the blender. Low speed stirring is recommended as SBR is a long chain polymer. If the rotation speed is too fast for a long time, the molecular chain will easily break and lose activity. It is recommended to stir at a low speed of 35-40rpm and a high speed of 1200-1800rpm for 10-20 minutes. Test viscosity (2000~4000 mPa.s), particle size (35um≤), solid content (40-70%), vacuum degree and screen mesh (≤100 mesh). Specific process values will vary depending on the physical properties of the material and the mixing process. The workshop requires temperature ≤30℃ and humidity ≤25%RH. Coating cathode coating The lithium battery manufacturing process refers to extruding or spraying the cathode slurry on the AB surface of the aluminum current collector, with a single surface density of ≈20~40 mg/cm2 (ternary lithium battery type). The furnace temperature is generally above 4 to 8 knots, and the baking temperature of each section is adjusted between 95°C and 120°C according to actual needs to avoid transverse cracks and solvent dripping during baking cracking. The transfer coating roller speed ratio is 1.1-1.2, and the gap position is thinned by 20-30um to avoid excessive compaction of the label position due to tailing during battery cycling, which may lead to lithium precipitation. Coating moisture ≤2000-3000ppm (depending on material and process). The positive electrode temperature in the workshop is ≤30℃ and the humidity is ≤25%. The schematic diagram is as follows: Schematic diagram of coating tape

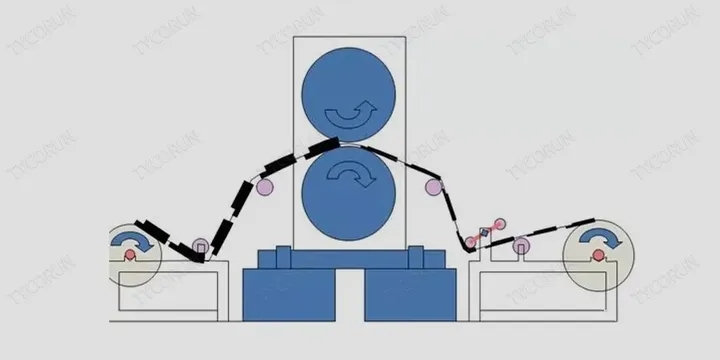

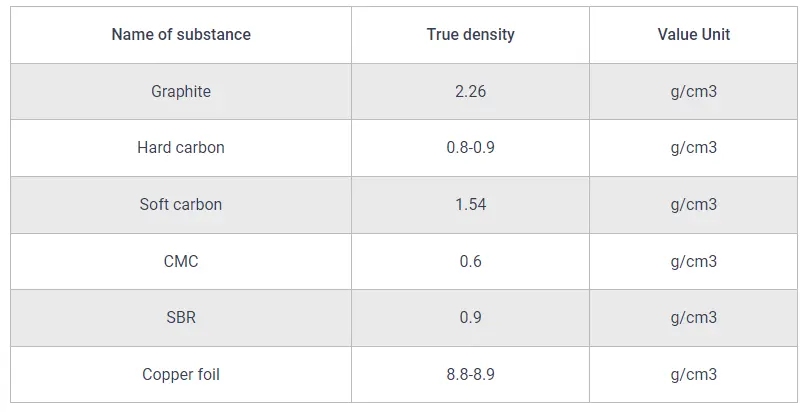

The lithium battery manufacturing process of negative electrode coating refers to extruding or spraying negative electrode slurry on the AB surface of the copper current collector. Single surface density ≈ 10~15 mg/cm2. The coating furnace temperature generally has 4-8 sections (or more), and the baking temperature of each section is 80℃~105℃. It can be adjusted according to actual needs to avoid baking cracks and transverse cracks. The transfer roller speed ratio is 1.2-1.3, the gap is thinned 10-15um, the paint concentration is ≤3000ppm, the negative electrode temperature in the workshop is ≤30℃, and the humidity is ≤25%. After the positive coating of the positive plate dries, the drum needs to be aligned within the process time. The roller is used to compact the electrode sheet (the mass of the dressing per unit volume). Currently, there are two positive electrode pressing methods in the lithium battery manufacturing process: hot pressing and cold pressing. Compared with cold pressing, hot pressing has higher compaction and lower rebound rate. However, the cold pressing process is relatively simple and easy to operate and control. The main equipment of the roller is to achieve the following process values, compaction density, rebound rate and elongation. At the same time, it should be noted that brittle chips, hard lumps, fallen materials, wavy edges, etc. are not allowed on the surface of the rod piece, and breaks are not allowed in the gaps. At this time, the workshop environment temperature: ≤23℃, humidity: ≤25%. The true density of current conventional materials:

Commonly used compaction:

Rebound rate: general rebound 2-3 μm

Elongation: Positive electrode sheet is generally ≈1.002

After the positive electrode roll is completed, the next step is to divide the entire electrode piece into small strips of the same width (corresponding to the height of the battery). When slitting, pay attention to the burrs of the pole piece. It is necessary to comprehensively inspect the pole pieces for burrs in the X and Y directions with the help of two-dimensional equipment. Longitudinal burr length process Y≤1/2 H diaphragm thickness. The ambient temperature of the workshop should be ≤23℃, and the dew point should be ≤-30℃. The manufacturing process of negative electrode sheets for lithium battery negative electrode sheets is the same as that of positive electrodes, but the process design is different. The ambient temperature of the workshop should be ≤23℃ and the humidity should be ≤25%. True density of common negative electrode materials:

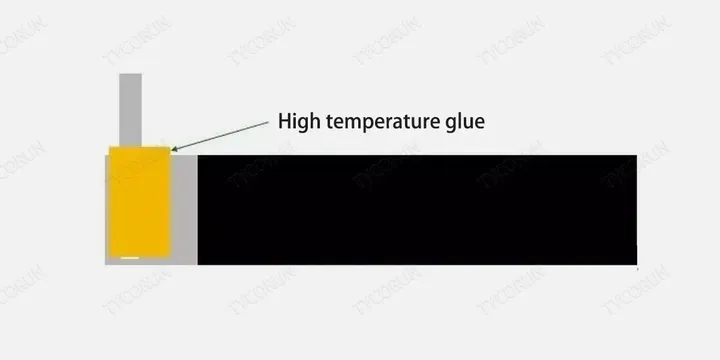

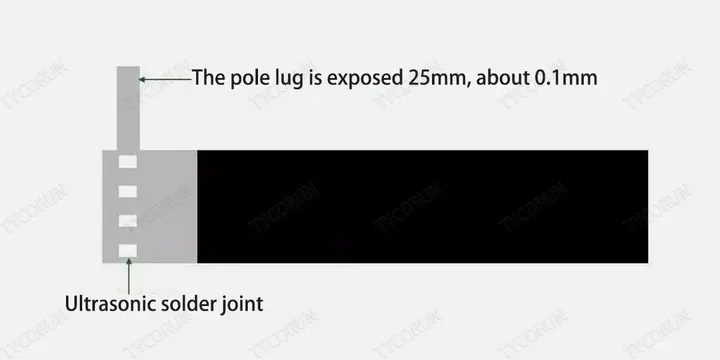

Commonly used negative electrode compaction: Rebound rate: General rebound 4-8um Elongation: Positive plate generally ≈ 1.002 The production process of lithium battery positive electrode stripping is similar to the positive electrode stripping process, and both need to control the burrs in the X and Y directions. The ambient temperature of the workshop should be ≤23℃, and the dew point should be ≤-30℃. After the positive plate is ready to be stripped, the positive plate needs to be dried (120°C), and then the aluminum sheet is welded and packaged. During this process, tab length and molding width need to be considered. Taking the **650 design (such as the 18650 battery) as an example, the design with exposed tabs is mainly to consider the reasonable cooperation of the cathode tabs during cap and roll groove welding. If the pole tabs are exposed for too long, a short circuit may easily occur between the pole tabs and the steel shell during the rolling process. If the lug is too short, the cap cannot be soldered. At present, there are two types of ultrasonic welding heads: linear and point-shaped. Domestic processes mostly use linear welding heads due to considerations of overcurrent and welding strength. In addition, high-temperature glue is used to cover the solder tabs, mainly to avoid the risk of short circuits caused by metal burrs and metal debris. The ambient temperature of the workshop should be ≤23℃, the dew point should be ≤-30℃, and the cathode moisture content should be ≤500-1000ppm.

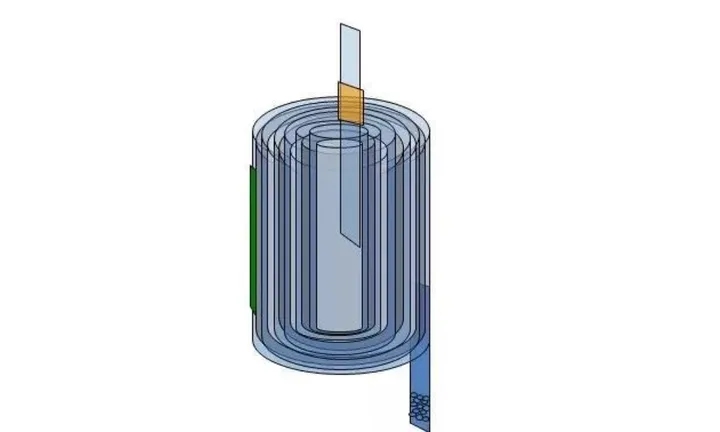

Negative Plate Preparation The negative plate needs to be dried (105-110°C), then the nickel sheets are welded and packaged. Solder tab length and forming width also need to be considered. The ambient temperature of the workshop should be ≤23℃, the dew point should be ≤-30℃, and the moisture content of the negative electrode should be ≤500-1000ppm. Winding is to wind the separator, positive electrode sheet and negative electrode sheet into an iron core through a winding machine. The principle is to wrap the positive electrode with the negative electrode, and then separate the positive and negative electrodes through a separator. Since the negative electrode of the traditional system is the control electrode of the battery design, the capacity design is higher than that of the positive electrode, so that during formation charging, the Li+ of the positive electrode can be stored in the “vacancy” of the negative electrode. Special attention needs to be paid to the winding tension and pole piece arrangement when winding. Too small winding tension will affect the internal resistance and housing insertion rate. Excessive tension may lead to the risk of short circuit or chipping. Alignment refers to the relative position of the negative electrode, positive electrode, and separator. The width of the negative electrode is 59.5 mm, the positive electrode is 58 mm, and the separator is 61 mm. The three are aligned during playback to avoid the risk of short circuits. The winding tension is generally between 0.08-0.15Mpa for the positive pole, 0.08-0.15Mpa for the negative pole, 0.08-0.15Mpa for the upper diaphragm, and 0.08-0.15Mpa for the lower diaphragm. Specific adjustments depend on the equipment and process. The ambient temperature of this workshop is ≤23℃, the dew point is ≤-30℃, and the moisture content is ≤500-1000ppm.

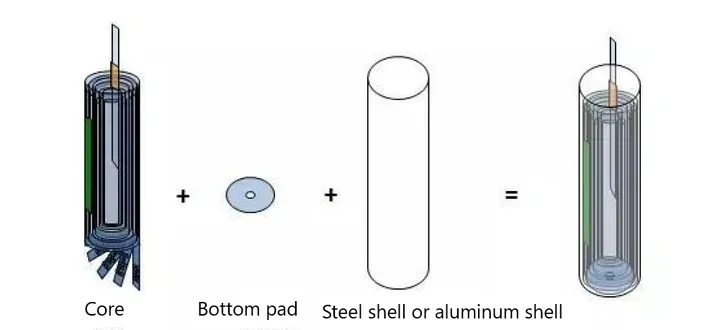

Before the cased battery core is installed into the case, a Hi-Pot test of 200~500V is required (to test whether the high-voltage battery is short-circuited), and vacuuming is also required to further control dust before being installed in the case. The three major control points of lithium batteries are moisture, burrs and dust. After the previous process is completed, insert the lower gasket into the bottom of the battery core, bend the positive electrode sheet so that the surface faces the battery core winding pinhole, and finally insert it vertically into the steel shell or aluminum shell. Taking type 18650 as an example, the outer diameter ≈ 18mm + height ≈ 71.5mm. When the cross-sectional area of the wound core is smaller than the inner cross-sectional area of the steel case, the steel case insertion rate is approximately 97% to 98.5%. Because the rebound value of the pole piece and the degree of liquid penetration during later injection must be considered. The same process as the surface underlayment includes the assembly of the top underlayment. The ambient temperature of the workshop should be ≤23℃, and the dew point should be ≤-40℃.

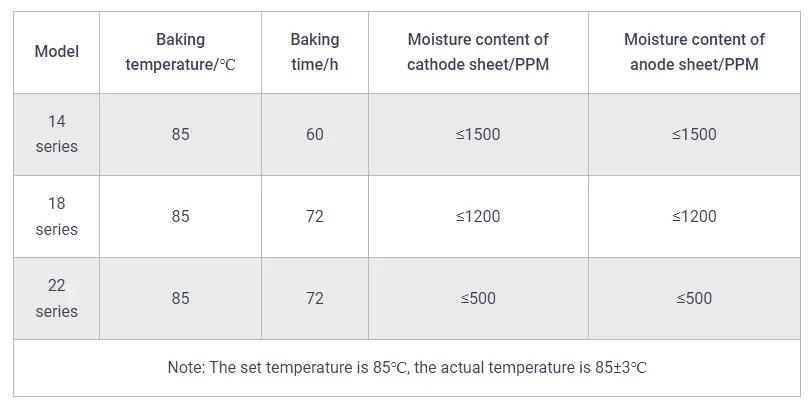

Rolling inserts a solder pin (usually made of copper or alloy) into the middle of the solder core. Commonly used welding pins are Φ2.5*1.6mm, and the welding strength of the negative electrode should be ≥12N to be qualified. If it is too low, it will easily cause virtual soldering and excessive internal resistance. If it is too high, it is easy to weld off the nickel layer on the surface of the steel shell, resulting in solder joints, leading to hidden dangers such as rust and leakage. The simple understanding of rolling groove is to fix the wound battery core on the casing without shaking. In the manufacturing process of this lithium battery, special attention should be paid to the matching of the transverse extrusion speed and the longitudinal pressing speed to avoid cutting the casing at a too high transverse speed, and the nickel layer of the notch will fall off if the longitudinal speed is too fast or the height of the notch will be affected and the sealing will be affected. It is necessary to check whether the process values for groove depth, extension and groove height comply with the standards (by practical and theoretical calculations). Common hob sizes are 1.0, 1.2 and 1.5 mm. After the rolling groove is completed, the entire machine needs to be vacuumed again to avoid metal debris. The vacuum degree should be ≤-0.065Mpa, and the vacuuming time should be 1~2s. The ambient temperature requirements of this workshop are ≤23℃, and the dew point is ≤-40℃. Battery core baking After the cylindrical battery sheets are rolled and grooved, the next lithium battery production process is very important: baking. During the production of battery cells, a certain amount of moisture is introduced. If the moisture cannot be controlled within the standard range in time, the performance and safety of the battery will be seriously affected. Generally, an automatic vacuum oven is used for baking. Arrange the cells to be baked neatly, put the desiccant into the oven, set the parameters, and raise the temperature to 85°C (taking lithium iron phosphate batteries as an example). The following are the baking standards for several different specifications of battery cells:

Liquid Injection The lithium battery manufacturing process involves humidity testing of the baked battery cells. Only after reaching the previous baking standards can you proceed to the next step: injecting the electrolyte. Quickly put the baked batteries into the vacuum glove box, weigh and record the weight, put on the injection cup, and add the designed weight of electrolyte into the cup (usually a liquid-immersed battery test is performed: put the battery into the cup middle). Put the battery core into the electrolyte, soak it for a period of time, test the maximum liquid absorption capacity of the battery (usually fill the liquid according to the experimental volume), put it into a vacuum box to vacuum (vacuum degree ≤ -0.09Mpa), and accelerate the penetration of the electrolyte into the electrode. After several cycles, remove the battery pieces and weigh them. Calculate whether the injection volume meets the design value. If it is less, it needs to be replenished. If there is too much, just pour off the excess until you meet the design requirements. The glove box environment requires temperature ≤23℃ and dew point ≤-45℃.

Welding During this lithium battery manufacturing process, the battery cover should be placed in the glove box in advance, and the battery cover should be fixed on the lower mold of the super welding machine with one hand, and the battery core should be held with the other hand. Align the positive lug of the battery cell with the terminal lug of the cover. After confirming that the positive terminal lug is aligned with the cap terminal lug, step on the ultrasonic welding machine. Then step on the welding machine’s foot switch. Afterwards, the battery unit should be fully inspected to check the welding effect of the solder tabs.

Observe whether the solder tabs are aligned.

Pull gently on the solder tab to see if it is loose.

Batteries whose battery cover is not firmly welded need to be re-welded.

Post time: May-27-2024